About:

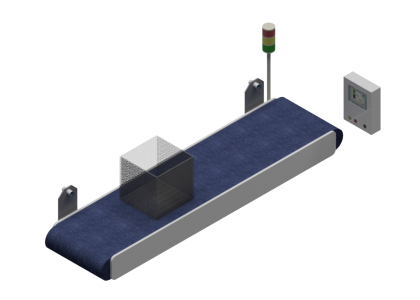

An example of a conveyor belt control solution with HMI panel and two operationg modes:

simulation and normal. In the simulation mode, the signals are not transmitted to physical

outputs and are not recieved from inputs. The project it based on Siemens hardware and was built

in TIA Portal and WinCC software (uses a sequencer).

Description:

The conveyor is driven by a DC motor. The transported elements are placed in metal containers.

The appearance of the container on the conveyor activates the input sensor,

which activates the drive (the conveyor moves).

When the container reaches to the end of the conveyor (output sensor), the conveyor stops.

After that the orange indicator flashes three times. It is not possible to restart the conveyor

until the container is removed.

The operator panel has three buttons: start, stop and reset alarm.

The alarm occurs in the situation when the container does not appear at the end

of the conveyor after 10 seconds. The start and stop buttons switch the device's ready status.

Connection scheme:

To connect, you need a PLC driver that supports a minimum of 6 inputs, 4 outputs

and is compatible with the Siemens TIA Portal software.

Inputs:

- Input Sensor

- Output Sensor

- START button

- STOP button

- RESET button

- Emergency STOP button

Outputs:

- Contactor for Motor

- Green Light

- Orange Light

- Red Light

HMI panel:

Panel allows you to simulate the layout by triggering of sensors, buttons and activating

the motor switching contactor. The current system status is indicated by LEDs.

Links:

- Step by step how to make it (YouTube) | LINK

- Selective printout from TIA Portal (PDF) | Download

How it works: